I have talked before about some watch designs that I’ve been thinking about for my first watch. See the article here.

Since writing this article I have also managed to finish my first British watch. Read the article here.

Originally I was going to make an ambitious regulator layout with retrograde hands, although once I calculated how much work was involved I decided to scale things down a little. Now I am satisfied to just start with a regulator layout, and once that is ready I can start thinking about grander designs.

This article will be a work in progress as I build my first watch. There won’t be a great deal I’ll be doing to the movement, just the modification of one wheel and the addition of two new ones. This will move the hour hand from the centre up to its position in the top sub dial.

I was going to pay to get someone to make the dial for me, but once I sat down and designed it out, I realised that actually I may be able to do it all myself. I’d certainly like to give it a shot anyway.

So here’s the design (for the moment at least):

So for the moment my to do list will be to make:

- Two new wheels

- Modify existing hour wheel

- A dial plate

- Two dial feet

- A chapter ring

- Two smaller chapter rings for the sub dials

- 3 hands

- 6 screws for chapter rings

The screws and hands will be made from steel and hand blued. The chapter rings will be made from brass, given a circular grain and then gold plated. The dial plate will be made from steel, given a straight grain and then either silver or rhodium plated (I’ll have to look into which finish will look better first before I finally decide). I’m thinking at the moment to rhodium plate the case and crown too.

Once I get this finished, I can start to think about other parts that I can make. I’m particularly keen on re-making the whole back plate, and also the crown, but we’ll see how this first part goes to start with. There’s no point trying to run before I can walk at this point, and so breaking it up into stages will make it easier to finish, and hopefully more satisfying to work on.

I do have a full-time job and am also doing the final year of the BHI exams at the same time so it’s not going to appear overnight, but I’ll update this as I progress…

Update Sept 2014:

It’s been a year since I last updated this, but there has been some progress in-between. As I have now taken my 3rd year BHI exams (and passed them), I have decided to incorporate the making of my watch into my 4th year portfolio. Completing the BHI’s 4th year exams will grant me the FBHI title (Fellow of BHI), and from what I can gather this will give you the closest to a doctorate in watchmaking that you can get.

For this I have to restore a number of watches, make parts and perform complex repairs. I have already picked out the watches I am going to work on and will include some of the parts that need to be made in my own watch.

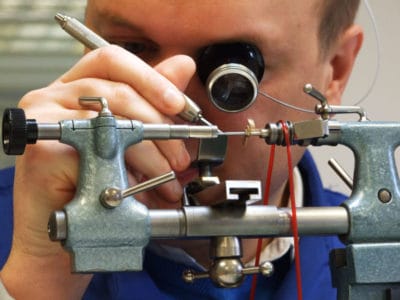

I have already made a balance staff and stem for the 6498 calibre, but as I feel as if I’m a bit out of touch of using my lathe I decided to try my hand at manufacturing and finishing some of the wheels; specifically the crown wheel and ratchet wheel, along with the click and the corresponding 3 screws that hold them in place.

Taylor Stiles

22 November, 2020 at 12:17 am

@stilesoftime Instagram

Colin,

Would you be willing to help explain a few things to me regarding the retrograde action? I’d love to incorporate one on my watch (6498-1) and am just struggling where to start. I understand the concept, it is more the math, and ratios of need help wrapping my brain around. Please feel free to email me at Taylor.stiles@gmail.com or via Instagram @stilesoftime. So appreciative.

TS

Colin

26 November, 2020 at 6:56 pm

Hi Taylor,

I’ll be happy to help where I can. I’ll be in touch via email.

Colin